Pictures of Fred's CNC Machine

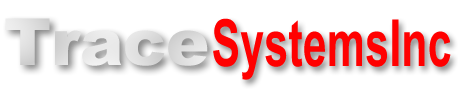

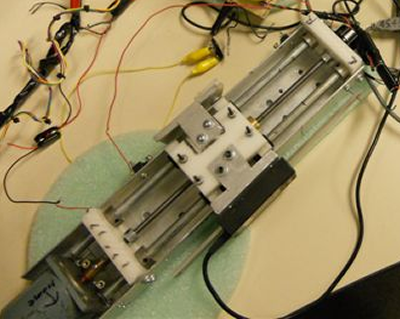

Since we posted Fred's story, I have been nagging him to provide some photos of what he has done. He finally send me this one photo, of one of his single axis devices.

I am still after him to send us some more photos, including one of his 2-axis whole machines. I will post more photos on a future blog post whenever I can get some. In the meantime I extracted some closeups of the individual sub-systems of this one axis device, to illustrate his explanations.

Here is a photo of a HID USB interfaced stepper motor CNC table. It uses the PIC18f4550 USB chip, and HIDmaker-generated PICBASIC Pro / Visual Basic 6 software.

The motors and drivers can be changed to analog motors and PWM drivers [if he wants]. The motor turns the 1/4-16 ACME lead screw and nut, which move moves the table and the attached Mitutoyo Digimatic SPC output scale.

"The Digimatic output displacement data is captured by the PIC18f4550 chip, assembled into HIDmaker VDD variables, and an Ep1 Xmt Rpt is sent to the pc.

The VB6 program receives and displays the displacement in the appropiate text box.

"The on/off, direction, and speed of the motor and table are controlled via the GUI.

And here is my favorite line from Fred's email:

"My work load has [been] greatly increased by my employer-- the more knowledge and ability you have, the more work they give you."

Got a comment on what you just read? Let us know - just add a comment below.

We'd love to hear from you!